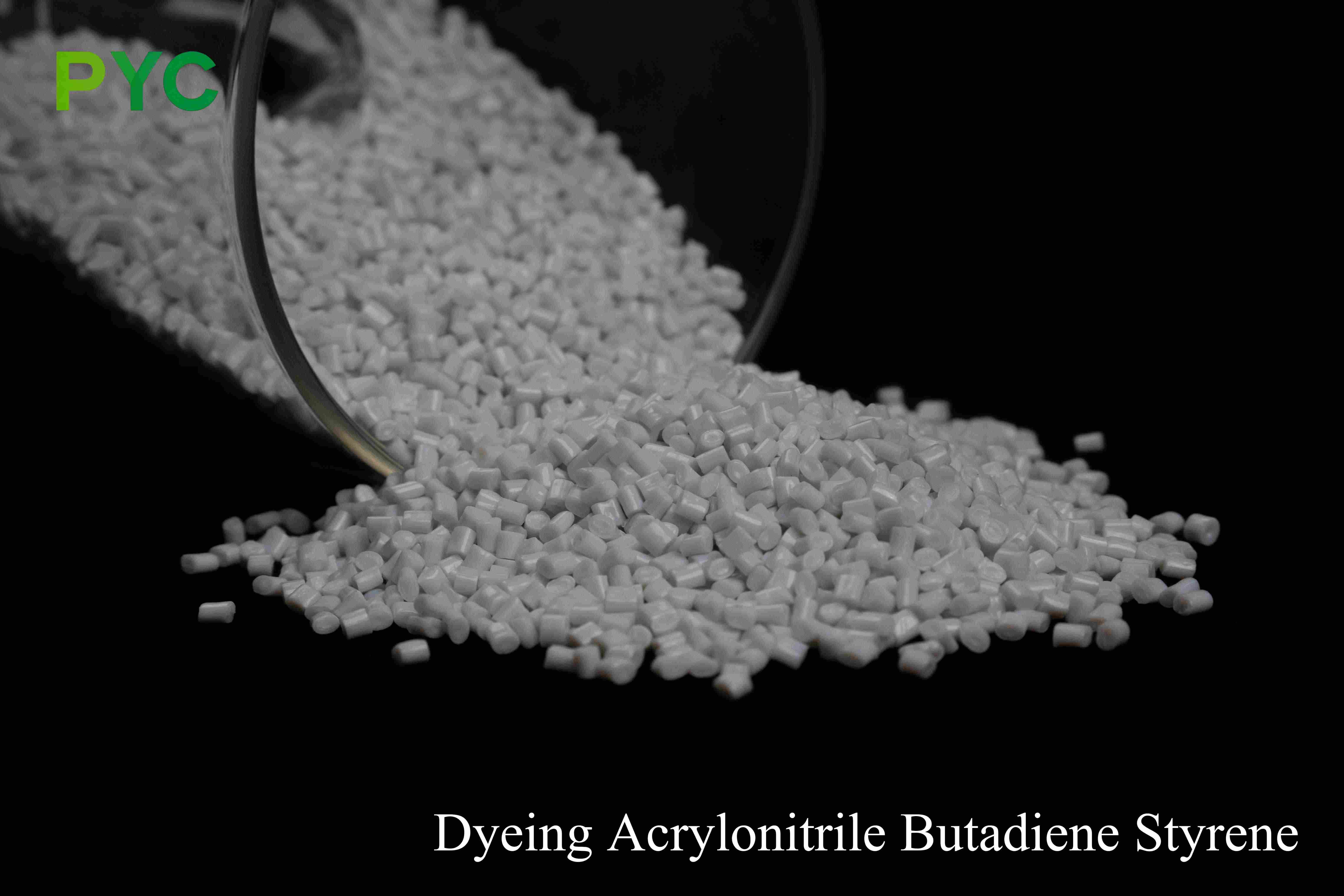

RPVC/ABS Alloy Plastics

Product Highlights

High quality ingredients

RPVC/ABS Alloy Plastics (RPVC/ABS Alloy Plastics) are alloyed with high purity recycled polyvinyl chloride (RPVC) and acrylonitrile butadiene styrene (ABS) materials, ensuring that the raw materials are sourced from reputable suppliers and are rigorously screened. Key recycling sources include:

Construction and piping materials: including waste pipes, window frames, door frames and building panels, the recycled RPVC material comes from construction waste that has been carefully screened and purified to ensure its high purity and stability, and is suitable for alloying to produce high-performance plastics.

Electronic equipment housing: including TV, monitor, computer housing, home appliance housing, etc. The recycled ABS material comes from electronic products, which is strictly screened and processed to ensure that it has excellent mechanical properties, impact resistance and processability.

Auto parts: including lamp shell, instrument panel, door interior trim, etc., recycled materials are screened and optimized to ensure that RPVC and ABS alloy has good impact resistance, heat resistance and durability.

Industrial waste and plastic packaging: including waste packaging materials, industrial parts, etc., after treatment and screening of recycled materials have low impurity content, to ensure that the processing stability and physical properties of the alloy meet the industry requirements.

By controlling the purity and stability of the raw materials through refinement, it ensures that the physical properties and processing adaptability of the final alloy materials meet the industry standards, and is widely used in construction, electronics, automotive and industrial fields.

Strict quality control

RPVC/ABS alloy plastics undergo a number of strict quality tests during the production process, including tensile strength, impact strength, heat resistance and dimensional stability tests, to ensure that the product has excellent mechanical properties and durability. All products comply with REACH and RoHS environmental certification and comply with environmental compliance requirements to ensure that customers are provided with high quality and environmentally friendly plastic solutions.

High performance applications - Suitable for automotive interior and exterior finishes, electrical housings, plumbing fittings, etc., with high impact strength and weather resistance to meet high-end manufacturing needs.

Environmentally sustainable -- Using recycled RPVC and ABS, the raw material recycling rate reaches 95%, in line with EU REACH and RoHS environmental standards, to help low-carbon transformation.

Flame retardant safety -- the material has passed UL 94 V0 flame retardant certification, has excellent fire resistance in high temperature environment, and is widely used in electronic and electrical industry.

Global layout - The products are exported to Europe, Southeast Asia and other 200+ customers, the annual export volume of more than 30,000 tons, covering the automobile, home appliances, construction and other industries.

Excellent production strength -- relying on intelligent production lines, the annual production capacity of 80,000 tons, stable quality, sufficient inventory, can quickly respond to global customer needs.

Product details

Technical process and quality assurance

RPVC/ABS alloy plastics combine the advantages of recycled polyvinyl chloride (RPVC) and ABS, with high strength, flame retardant and weather resistance. The company independently developed high-temperature melt blending technology to ensure the full fusion of the two polymers, improving material stability and processing performance. By adding anti-UV and anti-oxidation additives, the material can resist ultraviolet radiation and humid heat environment for a long time, and maintain mechanical properties and appearance quality. All products comply with REACH, RoHS and UL 94 V0 certification standards to ensure safety and environmental compliance.

Application scenarios and customer cases

RPVC/ABS alloy plastics have been widely used in electronic appliances, automotive industry, building materials and other fields. For example, in the automotive industry, the material is used in components such as dashboards, door panels and decorative strips to provide customized solutions for brand suppliers such as Mercedes Benz and BMW. In the field of electronics and appliances, the material is used in electrical shell, switch panel, cable sheath and other products, and has won the recognition of brand customers such as Haier and Midea with its excellent flame retardant and mechanical properties.

Production strength and sustainable development

The company has an intelligent production base with an annual capacity of 80,000 tons, and has established an industrial-grade testing laboratory to ensure stable product quality. At the same time, through the photovoltaic power generation + waste heat recovery system, the company reduces carbon emissions by 20,000 tons per year, and has been awarded the national green factory. RPVC/ABS materials adopt an efficient recycling system, and the utilization rate of raw materials reaches 98%, helping the global manufacturing industry to develop in the direction of green and low-carbon.

Innovative research and development and future planning

The company's research and development team is committed to the innovation of high-performance recycled materials and has developed new products such as glass fiber reinforced RPVC/ABS and low temperature resistant modified RPVC/ABS to meet a wider range of industrial needs. In the next three years, the company plans to invest 200 million yuan to build a 10,000-ton recycled engineering plastics base and promote the application and expansion of RPVC/ABS alloy plastics in emerging markets such as new energy vehicles, 5G electronics and smart homes.