OBP (Ocean Bound Plastic )

Ocean Bound Plastic (OBP) refers to discarded plastics that are transported to the edge of the ocean due to various natural factors before entering the ocean, and mainly originates from poorly managed areas with inefficient garbage disposal and within 50 kilometers of the coast. If these plastics are not recycled, they are very likely to enter the ocean, posing a serious threat to the marine ecosystem.

-

OBP PS

Product Highlights

Email Details

High quality recycled raw material source

OBP PS (Marine Plastic Recycled Polystyrene) is derived from plastic waste that is on the verge of entering the ocean and mainly includes:

Food packaging waste: disposable lunch boxes, foam trays, transparent plastic covers, etc.

Electronic product shell: PS material in the shell of discarded home appliances and electronic equipment.

Industrial scraps: PS waste produced in the production process, such as injection molding, extrusion, thermoforming scrap, etc.

These recycled materials undergo strict screening and cleaning treatment to remove impurities and contaminants, ensure raw material purity, and provide excellent product performance.

Strict quality control

Selected raw materials: only high purity PS waste is used to reduce impurity content and improve material stability.

Efficient cleaning: multiple cleaning process, remove oil, dust and other pollutants, to ensure the cleanliness of the material.

Fine regeneration: Optimize the melt regeneration process, improve the integrity of molecular structure, so that the material has excellent mechanical properties and thermal stability.

Quality testing: Each batch of products are tested by melt index (MFI), ash content, impact strength and other key indicators to ensure quality standards.

Excellent performance, widely used

OBP PS has good toughness, heat resistance and processing adaptability, suitable for:

Packaging industry: food containers, fast food boxes, foam packaging.

Electronic and electrical: TV shell, home appliance parts.

Building decoration: soundproof panels, decorative panels, lightweight filling materials.

OBP PS provides high-performance, environmentally friendly material solutions for sustainable development through high-purity selected raw materials and strict quality control. -

OBP TPU

OBP TPU (Ocean Bound Plastic Thermoplastic) is a thermoplastic elastomer made from recycled plastic waste that is close to entering the ocean. It combines excellent elasticity, wear resistance, chemical resistance and flexibility, and is widely used in footwear, electronic products, automotive industry and medical fields to meet the market's high-performance demand for environmentally friendly materials.

Email Details -

OBP PP

Product Highlights (Highlights)

Email Details

High purity selection of raw materials to ensure excellent quality

Choose a single source, high purity recycled PE (polyethylene), its recycling sources include:

Injection molding machine nozzle material

From the waste generated in the injection molding process, after screening to ensure that the purity of the material is high and no additional impurities, maintain good processing properties. -

OBP POM

Product Highlights (Highlights)

Email Details

Here, of course, is the version of the point-by-point narrative:

High purity selection of raw materials to ensure stable quality

Recycle POM (polyformaldehyde) with single source and high purity, its recycling sources include:

1. Water inlet material in precision injection molding

The waste from the injection molding process is screened to ensure high purity and no additional impurities. -

OBP MABS

OBP MABS product documentation

Email Details

Product Highlights

Ok, according to your request, I will write these recycled sources into the template:

High quality raw materials

Dyeing ABS is made of selected recycled ABS raw materials, which come from a single source and have been strictly screened by upstream manufacturers to ensure their purity and consistency. -

OBP PBT

Products (Highlights)

Email Details

High purity selection of raw materials to ensure excellent quality

Recycle PBT (polybutylene terephthalate) from a single source with high purity, and its recycling sources include:

Injection molding machine nozzle material

Waste from the injection molding process, screened to ensure high purity and no additional impurities, to keep the performance of the material stable. -

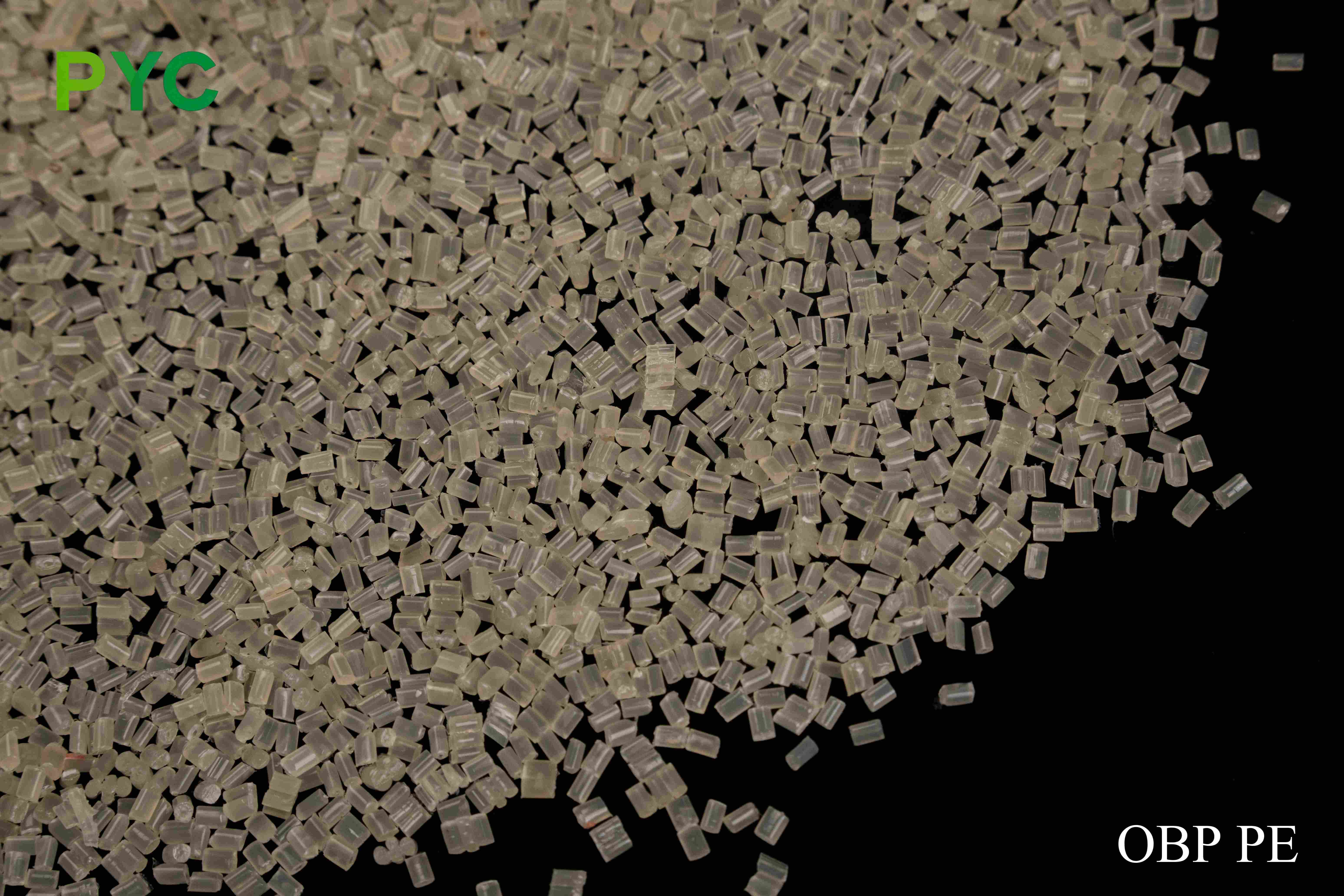

OBP PE

Our OBP PE (Ocean-Bound Plastic Polyethylene) is an environmentally responsible material derived from plastic waste collected near coastal areas, preventing it from entering the ocean. This sustainable alternative retains the excellent flexibility, durability, and chemical resistance of virgin PE while promoting a circular economy and reducing plastic pollution.

Email Details -

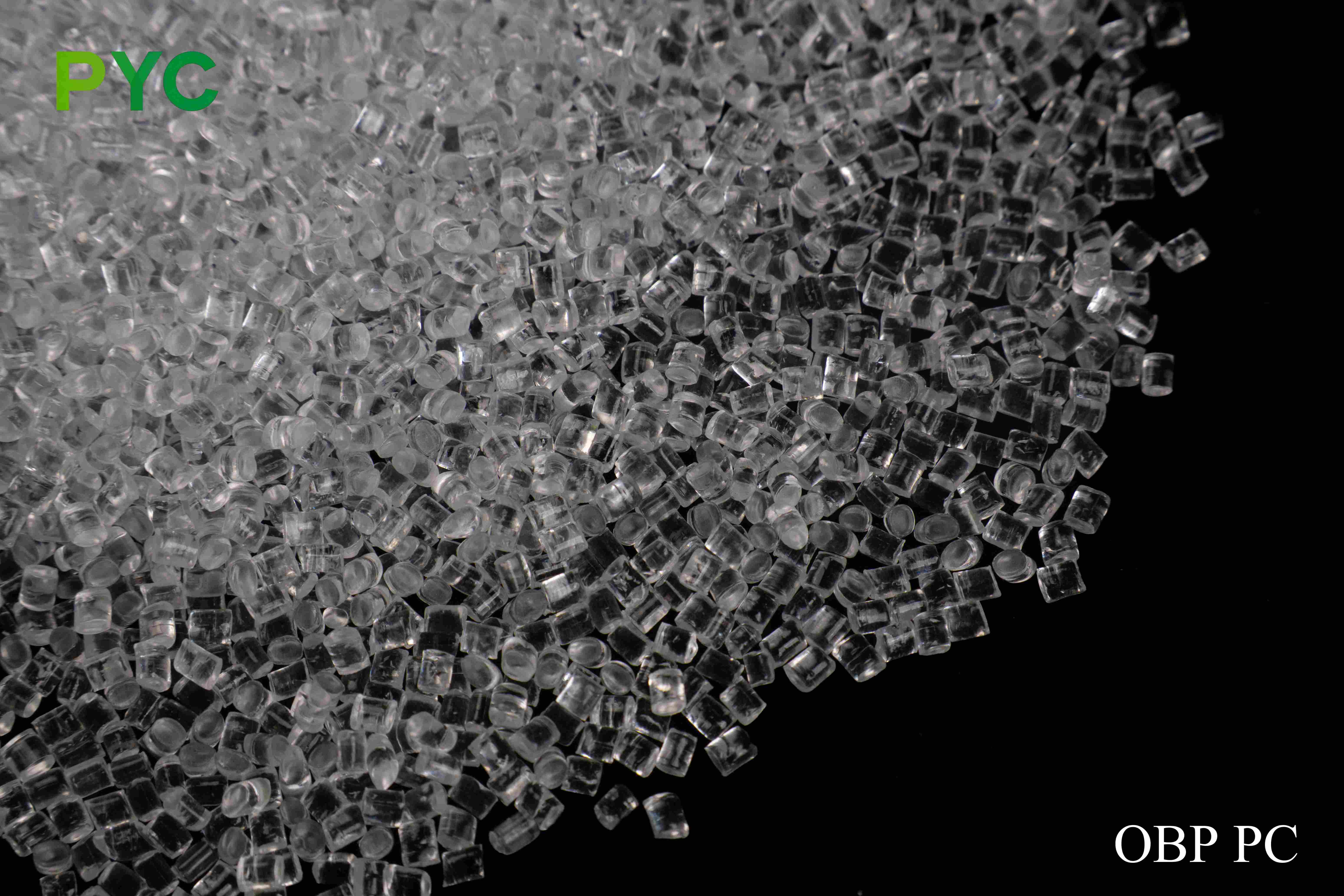

OBP PC

Our OBP PC (Ocean-Bound Plastic Polycarbonate) is a sustainable, high-performance engineering plastic derived from ocean-bound plastic waste collected near coastal areas. It retains the superior impact resistance, optical clarity, and heat resistance of virgin polycarbonate while reducing plastic pollution and supporting the circular economy.

Email Details -

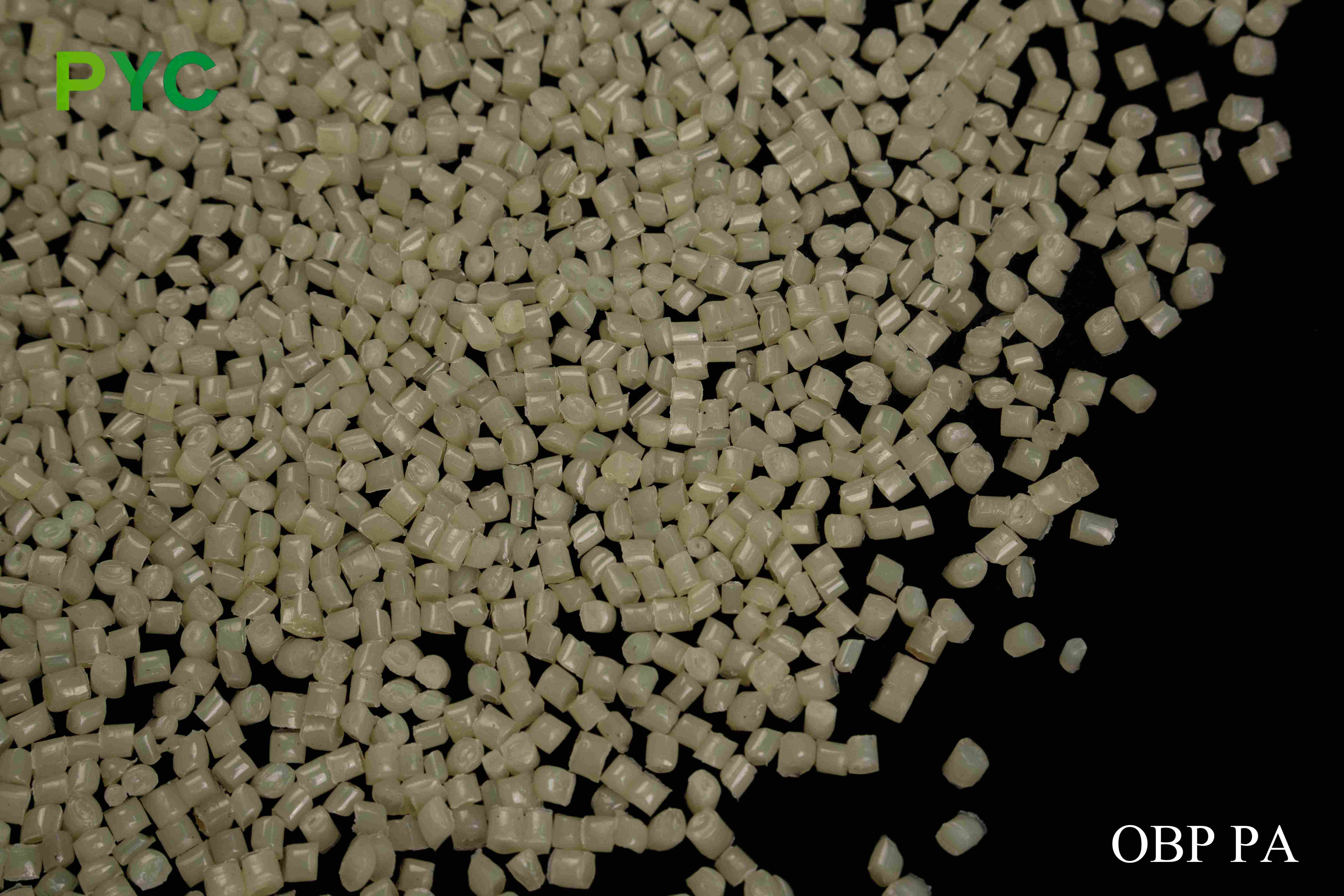

OBP PA

Our OBP PA (Ocean-Bound Plastic Polyamide) is an eco-friendly, high-performance material sourced from plastic waste collected near coastal areas, preventing pollution and promoting a circular economy. This recycled polyamide retains the excellent mechanical strength, durability, and chemical resistance of virgin PA, making it an ideal choice for industries seeking sustainable yet robust materials.

Email Details