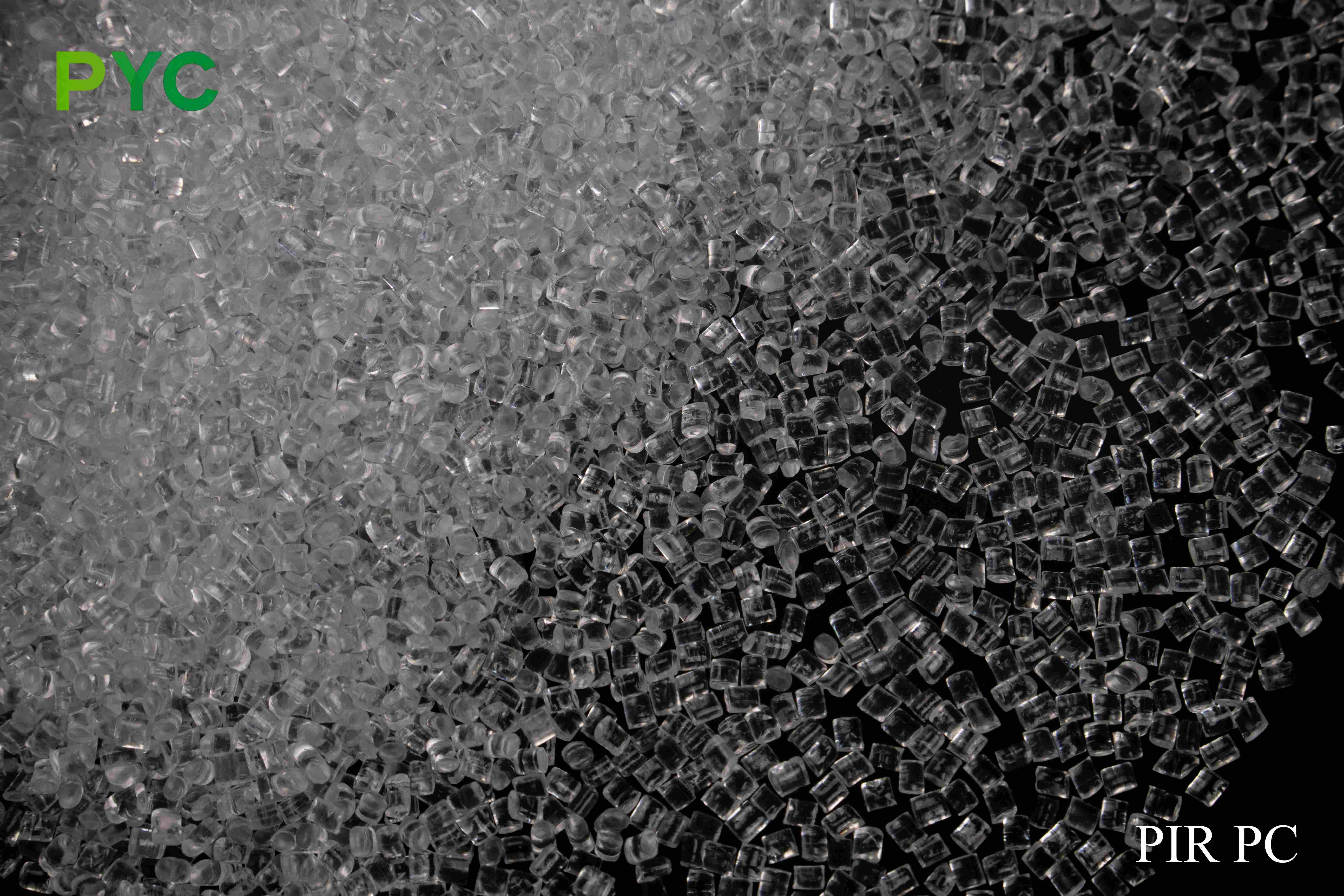

PIR PC

PIR PC (PostIndustrial Recycled Polycarbonate) - post-industrial recycled polycarbonate

PIR PC is an environmentally friendly plastic produced by recycling polycarbonate (PC) industrial waste, discarded plastic products, etc. Polycarbonate is a thermoplastic with superior properties, with excellent transparency, impact resistance and heat resistance. By recycling industrial waste polycarbonate materials, PIR PC can not only effectively reduce plastic waste, but also provide high-performance materials, which are widely used in electronics, automotive, construction and other industries.

Product Details

1. High-quality recycled feedstock sources

PIR PC's recycled raw materials are mainly from waste polycarbonate materials from industrial production, including:

Production waste: e.g. polycarbonate sheets, films, injection molding trimmings, etc.

Waste polycarbonate products: e.g., waste electronic product housings, lampshades, automobile interior parts, etc.

The

Waste optical products: such as discarded optical lenses, lenses and so on.

These waste materials are screened, cleaned and processed to transform them into high-quality PIR PC raw materials, ensuring their stability and environmental friendliness.

2. Strict quality control

PIR PC undergoes a number of stringent quality controls during the production process to ensure that each batch of material meets high standards. Tensile strength, impact resistance, transparency, heat resistance and other performance tests are passed to ensure high performance and stability of the products to meet the needs of various demanding applications.

3. Excellent performance

High Transparency: PIR PC has a transparency similar to that of newer materials and is suitable for applications requiring transparent materials such as optical lenses, lenses, displays, etc.

Excellent Impact Resistance: PIR PC has very high impact resistance and is able to withstand large external forces, making it suitable for use in applications where durability and impact resistance are required.

High Temperature Resistance: PIR PC maintains excellent performance in high temperature environments and is suitable for high temperature working environments such as electronics and automobiles.

Excellent Mechanical Strength: PIR PC has good strength and rigidity and is suitable for applications requiring high strength and stability, such as construction materials and electronic housings.

4. Environmental protection and sustainability

By recycling waste polycarbonate materials, PIR PC reduces dependence on new raw materials, minimizes waste of resources, and helps reduce the accumulation of plastic waste. The recycling process not only reduces production costs, but is also environmentally friendly and sustainable.

5. Cost-effectiveness

The cost of using PIR PC as a raw material for production is significantly lower than brand new polycarbonate materials. Due to the use of recycled materials, PIR PC is less expensive to produce, providing companies with a cost-effective plastic material that also helps to reduce the carbon footprint of production.

Application area

Electronic industry: PIR PC can be used for electronic product shell, display, mobile phone case, etc., with good impact resistance and transparency, can protect electronic products from external impact and influence.

Automotive industry: In the automotive field, PIR PC is used in automotive lighting, instrument panels, Windows, interior trim parts, etc., providing high strength, transparency and heat resistance to adapt to the complex working environment inside and outside the car.

Construction industry: Used for transparent panels, roof panels, Windows, etc., to provide high strength while maintaining good light transmittance and anti-ultraviolet performance.

Medical industry: PIR PC can be used in the production of medical equipment casings, transparent Windows, kits, etc., to meet the high requirements of material transparency and durability in the medical industry.

Product Advantages

High transparency: Compared with new materials, PIR PC has almost no difference in transparency, which is suitable for application scenarios requiring high transparency.

Strong impact resistance: PIR PC has excellent impact resistance and can resist various physical shocks in daily use.

High temperature resistance: It has good high temperature resistance and is suitable for application in high temperature working environment.

Environmental protection: The use of recycled materials, reduce the consumption of resources and waste generation, help to promote environmental protection and sustainable development.

Cost-effectiveness: Compared with new materials, the production cost of PIR PC is more competitive, helping enterprises to reduce production costs.

Production and technical advantages

Advanced recycling process: modern recycling technology is used to treat waste polycarbonate materials to ensure that their performance is close to that of new materials.

Extensive processing adaptability: PIR PC ADAPTS to a variety of processing methods, such

as injection molding, extrusion, blow molding, etc., and can be processed and customized according to different application needs.