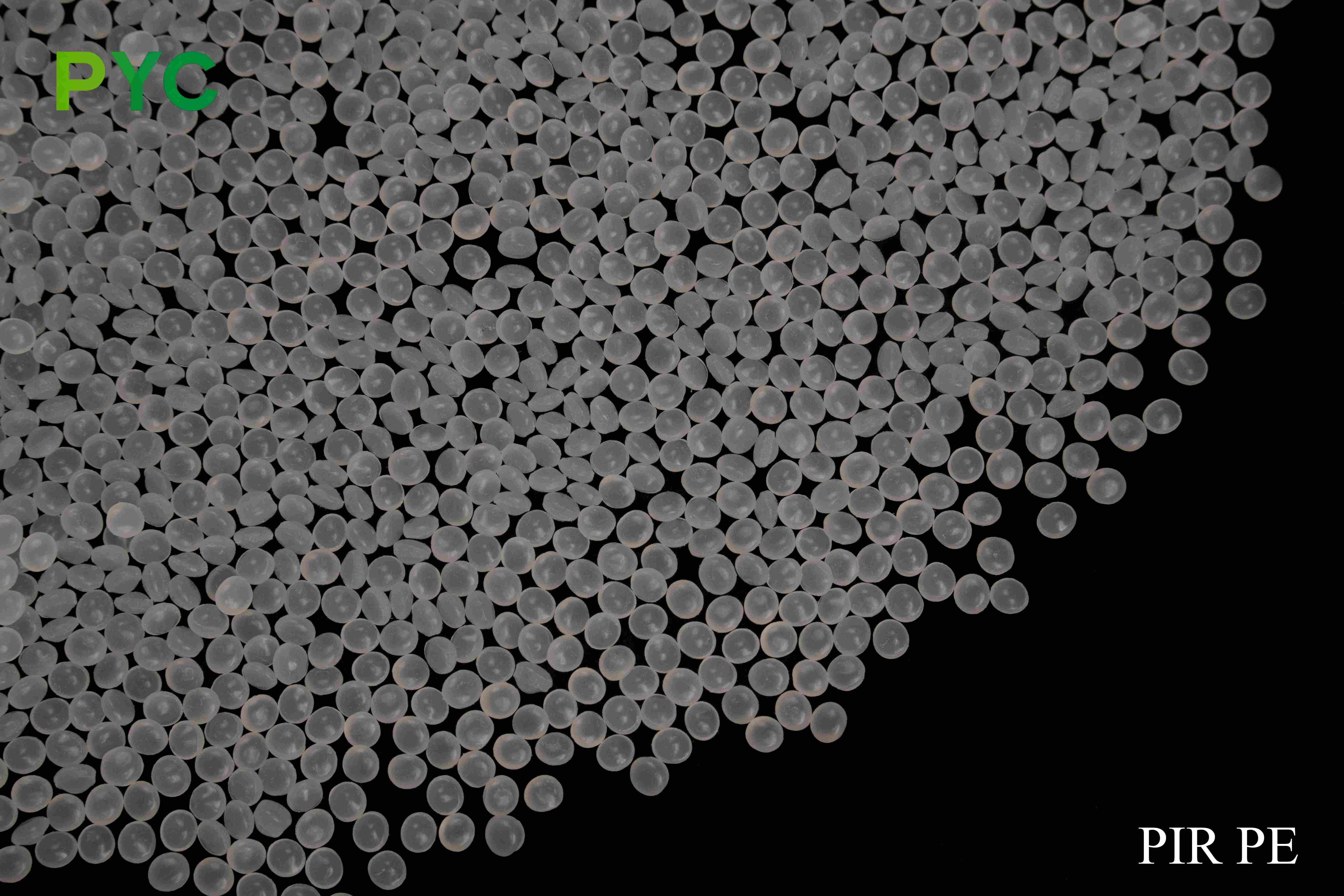

PIR PE

PIR PE (PostIndustrial Recycled Polyethylene) - Post-industrial recycled polyethylene

PIR PE is an environmentally friendly plastic produced by recycling industrial waste polyethylene (PE) material. Polyethylene is one of the most widely used plastics in the world and is widely used in packaging, plumbing, agriculture, construction and other industries due to its excellent flexibility, low temperature resistance and good chemical stability. PIR PE uses waste PE materials in industrial production for recycling and processing, which not only reduces the demand for new raw materials, but also reduces the impact of plastic waste on the environment, providing enterprises with sustainable solutions.

Product Details

1. High-quality recycled feedstock sources

The recycled feedstock for PIR PE is mainly from waste polyethylene materials from industrial production, including:

Production waste: such as PE film, PE plastic bags, packaging film, extrusion waste etc.

Waste plastic products: such as waste PE pipes, containers and bottles.

Industrial trimmings: Including PE trimmings waste generated in the production process, discarded PE packaging materials and so on.

These waste materials are screened, cleaned and processed to transform them into high-quality PIR PE raw materials, ensuring their environmental friendliness and consistent performance.

2. Strict quality control

PIR PE undergoes stringent quality control during the production process to ensure that each batch of material meets the standard requirements. Tests on tensile strength, impact toughness, melt index and other indicators are conducted to ensure the stability and reliability of the products in various applications.

3. Excellent performance

Good flexibility: PIR PE has good flexibility and is suitable for applications requiring a high degree of softness.

Low Temperature Resistance: PIR PE maintains good mechanical properties at low temperatures and is suitable for use in cold climates.

Chemical resistance: PIR PE has strong resistance to acids, alkalis, salts and other chemicals, and is widely used in packaging and piping.

Good Impact Resistance: PIR PE has strong impact resistance and is able to resist external physical impacts.

4. Environmental protection and sustainability

PIR PE reduces dependence on petroleum resources by recycling waste polyethylene materials and effectively reduces plastic waste emissions. The use of PIR PE not only meets environmental standards, but also helps to reduce CO2 emissions, promoting green production and sustainable development.

5. Cost-effectiveness

PIR PE is made from recycled materials, which reduces production costs and makes it more competitive compared to brand new polyethylene materials. The use of PIR PE helps companies to reduce production costs while maintaining high product quality and improving their competitiveness in the marketplace.

Application area

Packaging industry: PIR PE is often used in the production of food packaging, agricultural film, garbage bags, shopping bags, etc. Its excellent flexibility, transparency and low temperature resistance make it widely used in the packaging industry.

Pipeline industry: PIR PE can be used in the production of water pipes, gas pipes, drainage pipes, etc., with good chemical resistance and low temperature resistance.

Agricultural field: PIR PE is widely used in agricultural mulch film, irrigation pipeline, greenhouse film, etc., which can effectively protect crop growth and improve resource utilization.

Construction industry: used to manufacture building film, waterproof film, etc., to provide strong tensile strength and anti-ultraviolet performance, to adapt to the needs of the built environment.

Automotive industry: Used for automotive interior parts, automotive plastic parts, etc., with good flexibility and durability.

Product advantage

Good flexibility: PIR PE material is flexible and can withstand large deformation, suitable for applications that require softness and plasticity.

Low temperature resistance: PIR PE can still maintain good performance in low temperature environment, suitable for applications in cold areas.

Environmental protection: By recycling discarded PE materials, PIR PE helps to reduce the accumulation of plastic waste, in line with environmental protection and sustainable development requirements.

Cost-effectiveness: The use of PIR PE has lower production costs compared to new materials, providing enterprises with more competitive solutions.

Chemical resistance: PIR PE has good chemical resistance and can resist the corrosion of a variety of chemicals, which is suitable for applications requiring high chemical resistance environments.

Production and technical advantages

Advanced recycling process: PIR PE uses modern recycling technology to ensure that the quality of the material is close to the new material and meets the needs of various applications.

A variety of processing methods: PIR PE can be processed by injection molding, extrusion, blow molding and other ways, suitable for different product manufacturing needs.