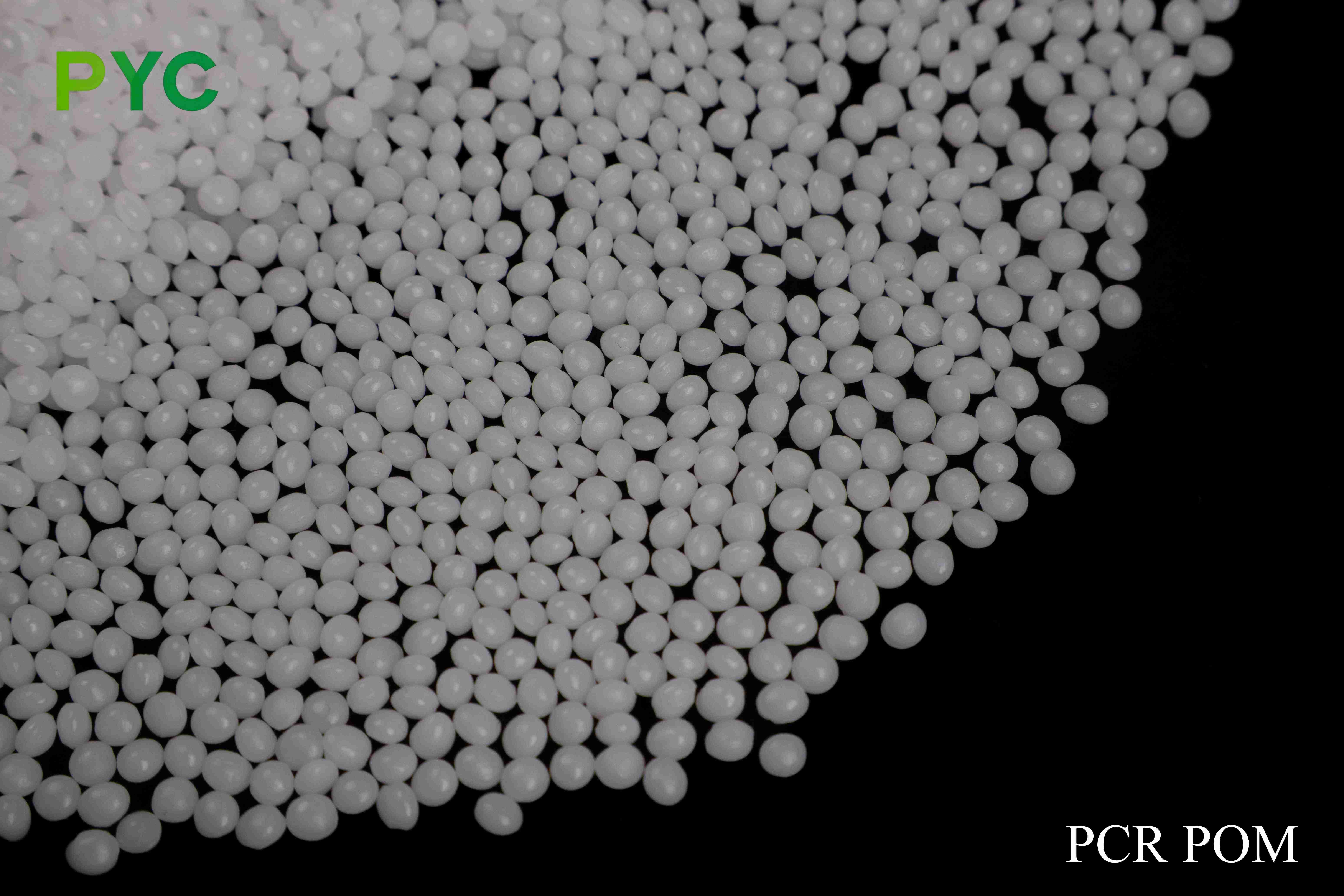

PCR POM

PCR POM (Post Consumer Recycled Polyoxymethylene) is a high-performance recycled plastic particle designed to meet the needs of modern industry. It uses high quality recycled polyoxymethylene raw materials and is widely used in automotive, electronics, appliances and mechanical components. PCR POM is an ideal choice for sustainable development due to its excellent mechanical properties and environmental friendliness.

Product Details:

High quality recycled raw materials

PCR POM is a high-performance engineering plastic made from recycled polyformaldehyde (POM) waste, which is widely used in many industries such as automotive, electronics, machinery and consumer goods.

The source of its recycled raw materials can be specifically divided into the following categories:

The automotive industry uses a large number of polyformaldehyde materials (POM), especially in automotive interior parts, engine parts, gears, valves and other components. During the scrapping process, these POM parts are disassembled and recycled, cleaned, treated and regenerated to be converted into high-quality PCR POM raw materials.

Electronic and electrical products

Polyformaldehyde is widely used in electronic products, such as electrical housings, connectors, switches, plugs, etc. After the used electronic and electrical products are scrapped, they will be disposed of through recycling channels. The POM parts in discarded electronic products are recycled and processed into recycled POM, which is used to make new products.

Consumer goods waste

POM materials are used in some appliances, office supplies and everyday consumer goods (e.g. components of office chairs, internal components of household appliances, etc.). These consumer goods at the end of the use period, through the garbage sorting, recycling process to extract the POM material, after treatment, become reusable PCR POM raw materials.

Waste mechanical parts of the polyformaldehyde material in many mechanical equipment has a wide range of applications, especially gear, bearings, sliding parts and so on. In the process of mechanical equipment elimination, the discarded POM parts can be converted into high-quality recycled polyformaldehyde materials after recycling and processing, which are used in the production of new mechanical parts.

Waste plastic products

Some plastic products, such as gears, rails, transmission system components, etc., often use polyformaldehyde as a raw material. The plastic products after use are screened out in the recycling system, and after cleaning and processing, they are converted into high-quality PCR POM raw materials.

Waste consumer electronic accessories include mobile phone shell, computer accessories, printer parts, etc., and polyformaldehyde is commonly used as a supporting material in these products. Through disassembly and recycling, the discarded POM parts are extracted and processed into high-quality PCR POM.

Recycling process

Recycled POM materials usually go through several steps as follows:

Preliminary screening: Different types of waste (such as vehicle parts, electrical accessories, etc.) are sorted to extract POM materials.

Cleaning and decontamination: Waste materials will be efficiently cleaned to remove impurities such as oil, dust, coating and so on to ensure the purity of recycled materials.

Pulverization and melting: The cleaned POM material will be pulverized into small particles, which will then be reshaped into new recycled particles through a melting process.

Quality testing: Each batch of recycled PCR POM will undergo strict quality testing, including tensile strength, wear resistance, heat resistance and other indicators, to ensure that it meets the requirements of use.

In this way, the recycling process of PCR POM effectively reduces the impact of waste plastics on the environment while providing a cost-effective and environmentally friendly raw material option.

Excellent mechanical properties:

PCR POM has extremely high rigidity, strength and wear resistance, making it superior in high load and high friction application scenarios. At the same time, its good impact resistance and fatigue resistance make the product maintain stable performance in long-term use.

Environmental protection and sustainability:

The preparation process of PCR POM not only reduces the use of new materials, but also effectively reduces the generation of plastic waste, which is in line with the global trend of sustainable development. By using PCR POM as a material, companies can actively participate in the cause of environmental protection while meeting production needs.

A wide range of applications:

PCR POM is widely used in the automotive industry interior parts, connectors and switches of electronic products, mechanical parts and so on. Its high wear resistance and excellent mechanical properties make it an ideal choice for a variety of demanding applications.

Field of application

PCR POM is widely used in automotive, electronics, electrical appliances, machinery and other industries. For example, in the automotive industry, PCR POM can be used to manufacture gears, bearings, and interior trim parts. In the electronics industry, PCR POM is commonly used in components such as high-performance connectors and switches, ensuring the reliability and durability of equipment.

Product performance and benefits

PCR POM particles have excellent physical and chemical properties, including high rigidity, low friction coefficient and excellent chemical resistance. Its good stability and heat resistance make it suitable for use in high temperature and humid environments, ensuring the long-term reliability of the product.

Production and technical advantages

The production process of PCR POM uses advanced recycling technology and fine processing technology to ensure high quality and consistency of particles. Through the optimized production process, PCR POM can adapt to a variety of molding processes such as injection molding and extrusion to meet the different product needs of customers.

Environmental protection and cost effectiveness

As a recycled material, PCR POM helps companies reduce their dependence on new raw materials and reduce their environmental impact. At the same time, the use of PCR POM particles can effectively reduce production costs, improve the economic benefits of enterprises, and provide a strong support for sustainable development.

In short, PCR POM has become the first choice for high-performance recycled plastics with its excellent performance, environmental protection advantages and wide application fields. It not only meets the high standard needs of various industries, but also provides the ideal solution for enterprises to achieve green production and sustainable development goals.