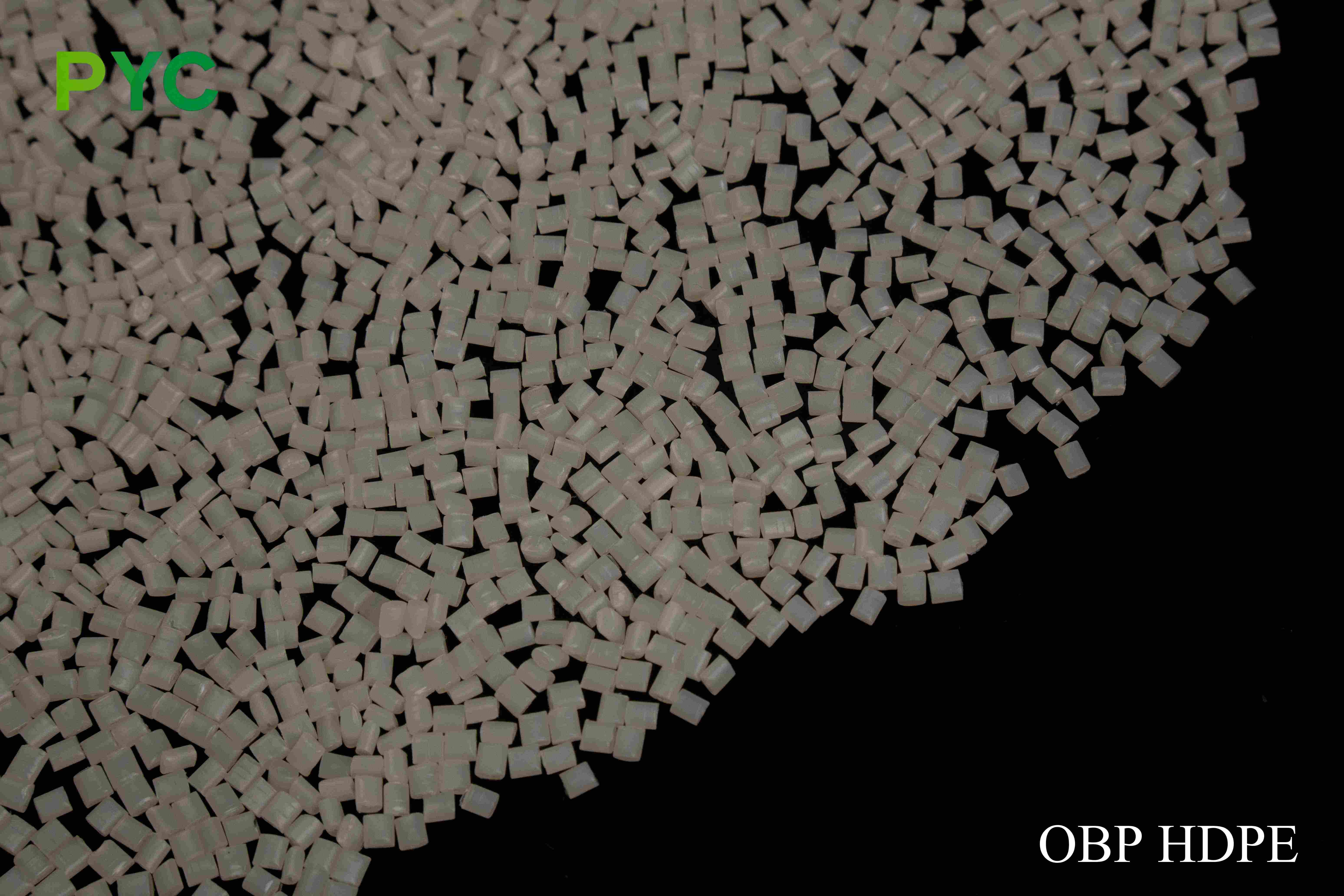

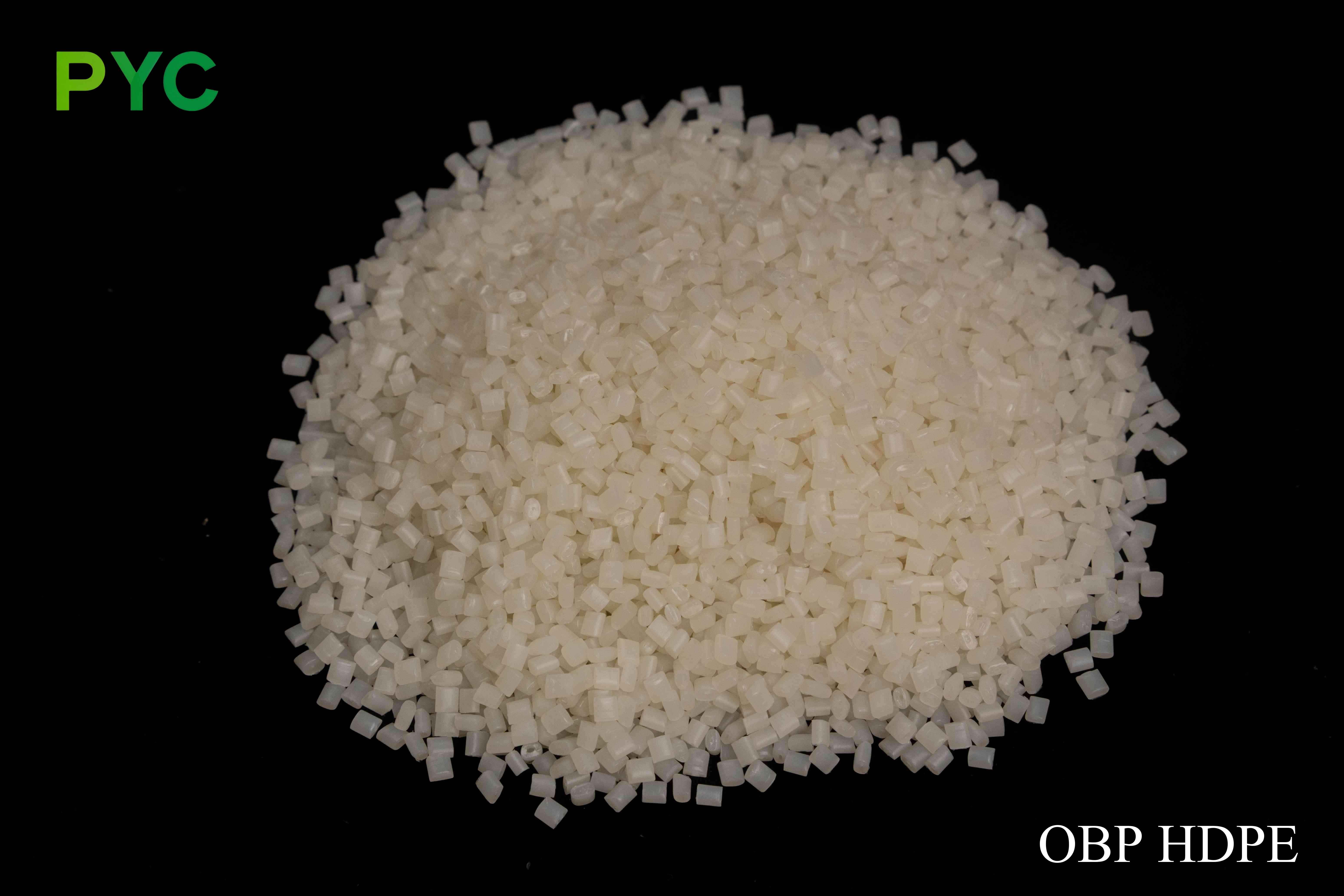

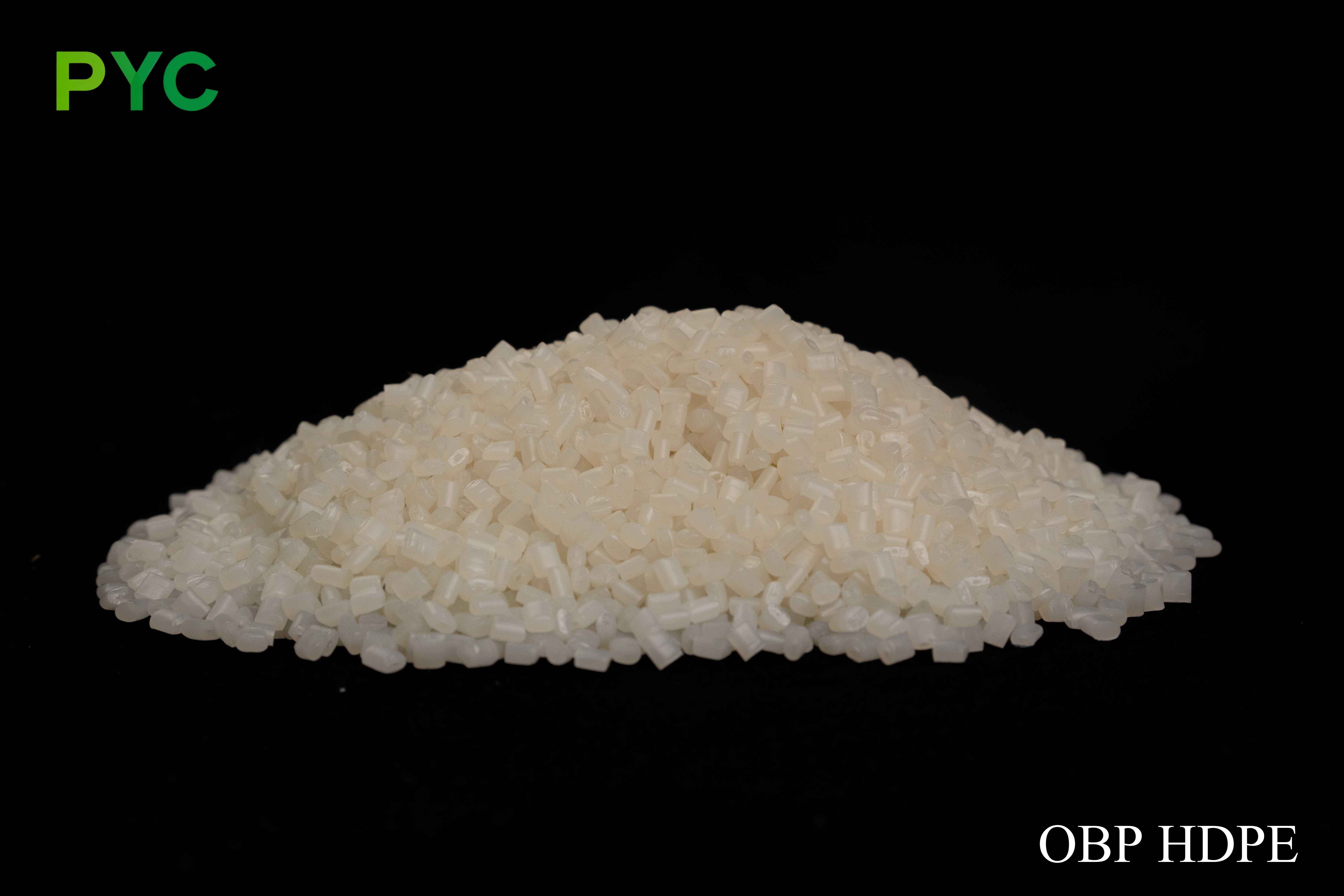

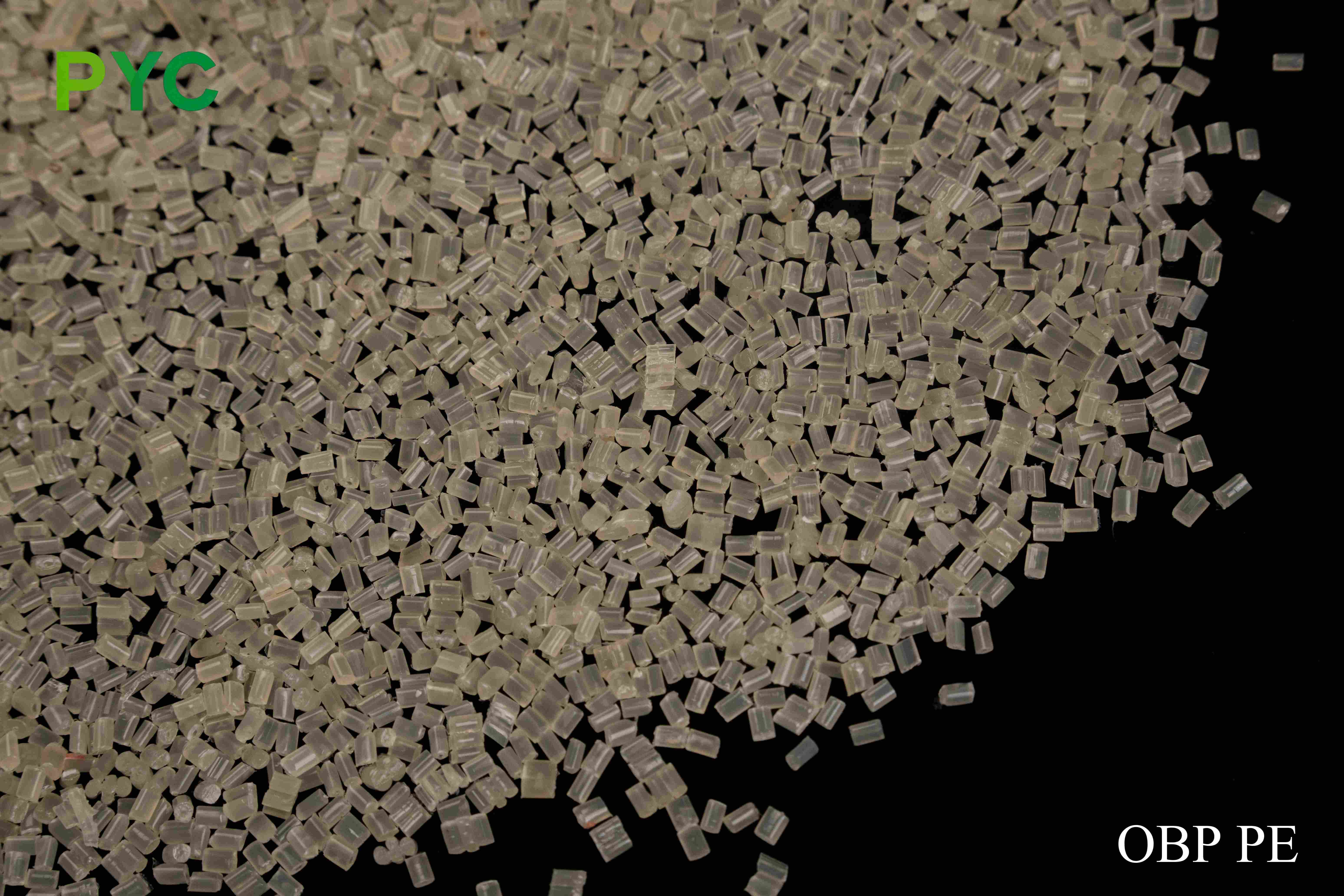

OBP HDPE

OBP HDPE is an environmentally friendly material made by recycling Ocean Bound Plastic (OBP) waste, consisting mainly of high-density polyethylene (HDPE). Ocean bound plastic refers to those plastic waste that comes within 50km of the shoreline and often ends up in the ocean, causing serious environmental pollution. By recycling this plastic waste, OBP HDPE not only helps to reduce plastic pollution, but also promotes the recycling of resources and environmentally friendly production, in line with sustainable development requirements.

Product Details

1. High-quality recycled feedstock sources

OBP HDPE's recycled feedstock is derived from plastic waste from marine boundary areas, specifically:

Waste plastic bottles and containers: e.g., beverage bottles, detergent bottles, etc., which are usually residential household waste or plastic waste from coastal areas.

Waste plastic products: e.g. bags, plastic pipes, food containers, fishing nets, etc., which can be converted into high-quality OBP HDPE feedstock after treatment.

Beach Cleanup Recyclables: Plastic waste recovered from beach cleanup operations is cleaned and processed into usable recycled materials.

Through this recycling process, plastic debris at ocean borders is effectively cleaned up and reused, thereby reducing plastic pollution and promoting a circular economy and sustainable development.

2. Strict quality control

During the production process, OBP HDPE undergoes stringent quality control to ensure that each batch meets international standards. Recycled plastic waste is finely screened, cleaned, sterilized and treated to remove impurities and ensure the purity and stability of the raw material. A series of stringent tests, including tensile strength, impact resistance, chemical resistance, etc., are conducted during production to ensure the stability and high quality of the products.

3. Excellent performance

High Density and Rigidity: OBP HDPE has high density and strength, making it excellent in compression and tensile strength for applications that are load-bearing or require high rigidity.

Chemical resistance: OBP HDPE has strong resistance to many chemicals and solvents, suitable for chemical packaging, food packaging and so on.

UV Resistant: OBP HDPE is suitable for outdoor applications as it maintains long term stability when exposed to the outdoor environment and does not age easily.

High Temperature Resistance: OBP HDPE has good high temperature resistance, can maintain its structural stability at higher temperatures, and is suitable for some applications in high temperature environments.

Excellent processing performance: OBP HDPE is suitable to be processed in various ways, including extrusion, injection molding, blow molding, etc., to meet the needs of different product forms.

4. Environmental protection and sustainability

OBP HDPE utilizes recycled marine boundary plastic waste as raw material, which helps to reduce marine pollution and the accumulation of plastic waste. At the same time, it meets environmental requirements, reduces dependence on petroleum resources, and promotes sustainable development by reducing CO2 emissions.The production process of OBP HDPE not only reduces production costs, but also helps companies to cope with increasingly stringent environmental regulations.

5. Cost-effectiveness

Because OBP HDPE uses recycled materials, production costs are relatively low. OBP HDPE offers a cost advantage over traditional petroleum-based HDPE materials, while it provides an environmentally friendly and sustainable solution for businesses. By recycling OBP, companies not only reduce the cost of raw material purchases, but also help to enhance the environmental image of their brands.

Application area

Packaging industry: OBP HDPE is widely used in the manufacture of various plastic containers, bags, bottles, etc., especially suitable for packaging food, beverages, chemicals, etc., to provide excellent protection.

Pipe industry: OBP HDPE is suitable for the production of all kinds of pipes, such as water supply and drainage pipes, agricultural irrigation pipes, etc., because of its good corrosion resistance and durability.

Automotive industry: OBP HDPE can be used in automotive parts, such as car bumpers, interior panels, etc., to provide enough rigidity and durability.

Construction industry: OBP HDPE also has applications in the construction industry, especially in the manufacturing of waterproof film, protective film and other fields, taking advantage of its excellent weather resistance and high temperature resistance.

Outdoor products: Due to its UV resistance properties, OBP HDPE is suitable for manufacturing outdoor furniture, gardening products, storage bins, etc.

Product Advantages

Environmental protection: OBP HDPE is made by recycling Marine boundary plastic waste, which significantly reduces the pollution of plastic waste to the ocean, in line with the concept of sustainable development.

High density and strength: The high density and strength of OBP HDPE make it suitable for use in products that require load bearing and durability, such as pipes, containers, etc.

Chemical resistance: OBP HDPE has strong chemical resistance and is suitable for chemical packaging, food packaging and other industries.

Weather resistance: OBP HDPE remains stable in long-term exposure to sunlight, suitable

for outdoor applications, such as horticulture, construction and other fields.

Strong processing adaptability: OBP HDPE can be produced through a variety of processing methods (such as injection molding, extrusion, blow molding, etc.) to meet different product needs.

Production and technical advantages

Advanced recycling technology: OBP HDPE uses advanced recycling technology to ensure that Marine boundary plastic waste can be effectively converted into high-quality plastic raw materials.

Environmentally friendly production process: The production process focuses on energy conservation and emission reduction, reducing the consumption of natural resources, and reducing carbon dioxide emissions in the production process.

A wide range of processing methods: OBP HDPE has excellent processing adaptability, can be processed by extrusion, blow molding, injection molding and other ways to meet the needs of various product forms.