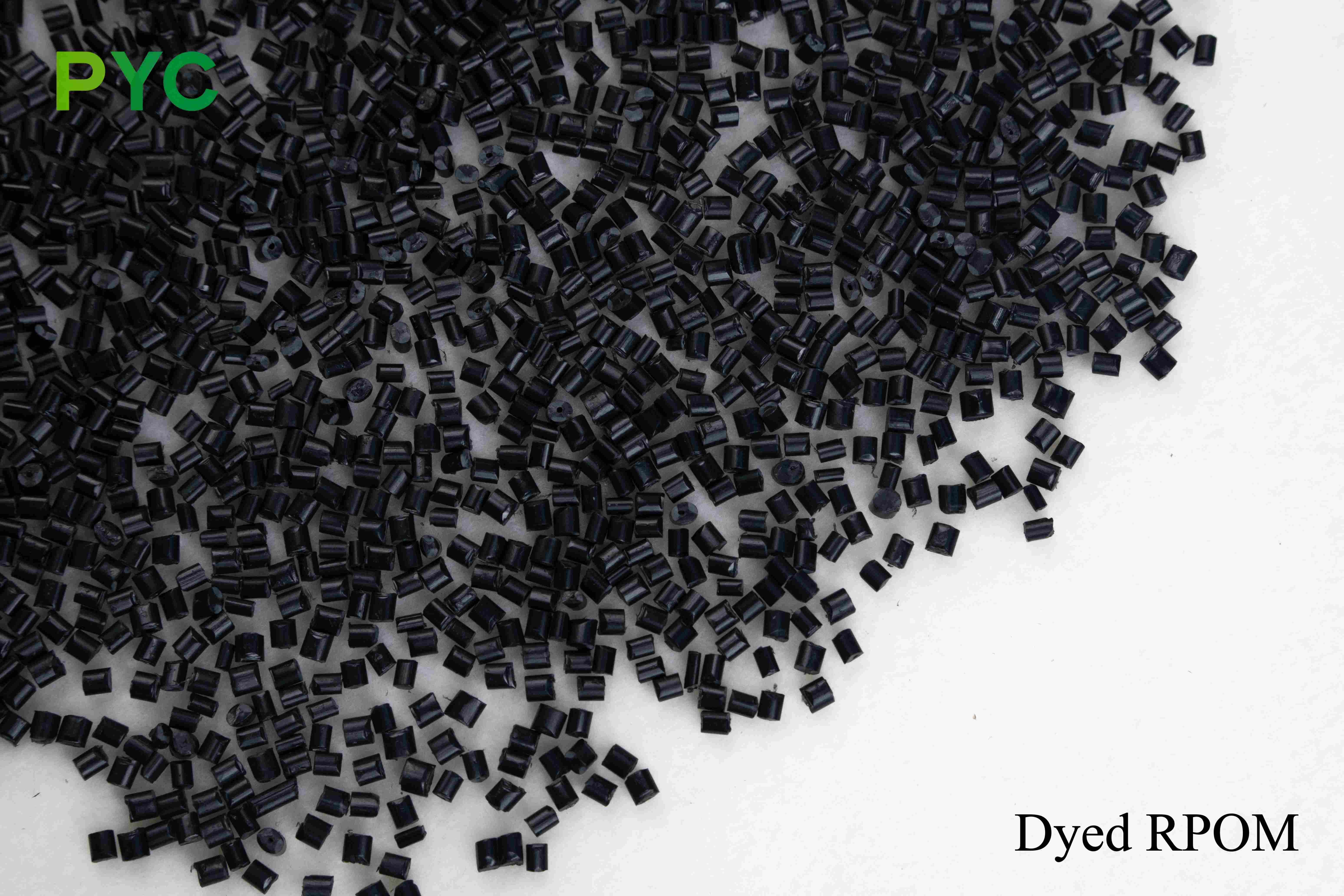

Dyed RPOM

High quality recycled raw materials

Dyed RPOM uses carefully selected recovered polyester (PET) from a single source as a base material, derived mainly from industrial waste, bottle flakes and other recyclable polyester materials. All raw materials were provided by certified upstream suppliers and underwent rigorous screening and cleaning treatment to ensure extremely low impurity content, ensuring the color uniformity and physical properties of the products, making the final product outstanding in terms of color consistency and quality stability.

Select Recycling sources

Industrial waste: includes scraps and scrap produced during polyester production, most of which come from plastic manufacturing plants and the packaging industry, such as residues produced during polyester fiber production or plastic film cutting scraps. All waste is rigorously screened and cleaned to remove any impurities that may affect the quality and ensure its low impurity content.

Bottle flakes: Recycled PET bottle flakes derived from recycled materials such as mineral water bottles and beverage bottles. These bottles are usually cleaned and de-labeled to ensure that no label or ink remains, preserving the purity of the PET. These bottle sheets, one of the main sources of recycled PET, are carefully screened to ensure no contaminants and are suitable for use in the production of high-quality Dyed RPOM.

Other recyclable polyester materials: Include waste from other PET products, such as PET plastic parts that are not used in the production process, such as cutlery packaging, food containers, etc. These materials are initially screened and cleaned to ensure they are low in impurities and to guarantee the consistency and reusability of the material.

Through careful screening and handling, Dyed RPOM ensured a high purity of the raw materials and extremely low impurity content, while maintaining the stability and predictability of the materials. This material not only ensured the color uniformity of the products, but also ensured the excellent mechanical properties and durability of the products, particularly suitable for applications requiring high performance and high visual requirements, such as textiles, packaging materials and high-end plastic products.

Strict quality control

Dyed RPOM uses advanced dyeing techniques to ensure stable and lasting colour, conforming to high standards. Strict quality control was carried out during the production of each batch of products, including dyeing uniformity, UV resistance and physical properties tests, to ensure that while meeting the demands for high performance, the products had excellent durability and environmental adaptability.

Environmentally friendly and sustainable:

Dyed RPOM, produced from recycled polyolefin materials, complied with global green standards and reduced reliance on new resources while reducing the environmental impact of plastic waste. Through the recycling and reuse of plastics, Dyed RPOM supports the circular economy and contributes to sustainable use of resources.

A variety of colour options:

Through dyeing, Dyed RPOM was able to provide a variety of color choices to meet customers' color needs in different application scenarios. Whether it is for the beauty of the appearance of products or the unity of brand identities, Dyed RPOM can help enterprises improve the appearance quality of their products and increase market competitiveness.

Excellent mechanical properties:

Dyed RPOM has the same excellent mechanical properties as ordinary RPOM, including excellent wear resistance, chemical resistance and high temperature resistance. It can remain stable under harsh environmental conditions, and is widely used in many fields such as automobiles, home appliances and electronic equipment, meeting the needs of high strength and high temperature applications.

Lightweight and cost effective:

Dyed RPOM's lower density effectively reduces the overall weight of products, dyed RPOm is especially suitable for applications requiring weight reduction, such as automotive parts and electronic casings. In addition, Dyed RPOM has lower production cost due to the use of recycled materials, which helped enterprises reduce manufacturing costs while meeting performance requirements.

Application scenario:

Dyed RPOM is applied to a wide range of industry sectors, especially in industries such as automobiles, home appliances, electronics, packaging and consumer goods. In the automotive industry, Dyed RPOM is often used in vehicle interior and exterior ornaments, instrument panels, seat components, etc., to both provide high strength and high temperature resistance, while satisfying customers' personalized needs for appearance colors. In the field of home appliances, Dyed RPOM was used in products such as refrigerators and washing machine shells, which enhanced the market appeal of the products through a variety of color choices. In addition, Dyed RPOM was also widely applied to packaging materials to provide environmentally-friendly packaging solutions with customized colors.

Case studies:

Dyed RPOM has been successfully applied to a number of internationally renowned brands. For example, Dyed RPOM was chosen by a car brand in the interior parts of its latest models, which not only ensured the strength and durability of the parts, but also allowed dyed RPOM to provide customized color matching to meet the unified style of the brands. In the home appliance industry, Dyed RPOM was applied to the shell materials of several home appliance products, which were able to resist prolonged use and ultraviolet exposure, and maintained the bright colors without fading.

Research and development techniques:

Dyed RPOM's research and development combined efficient polyolefin recycling processes with advanced dyeing techniques. Through the high-temperature dyeing process, RPOM was able to absorb the dye evenly and maintain long-term color stability. The research and development team has continued to innovate in improving Dyed RPOM's color stability, weather resistance and UV resistance, ensuring that Dyed RPOM maintains its excellent performance and aesthetic appearance in a variety of applications.

Production strength:

The company has strong production capacity and rich technical experience. Advanced recycling and dyeing techniques were adopted in the production line to ensure that each batch Dyed RPOM reached high quality requirements in terms of color consistency, mechanical properties and environmental standards. The production equipment has an efficient production capacity, which is able to meet the needs of large-scale orders and ensure that the products remain stable in quality during the production process.

Sales volume and inventory:

Dyed RPOM's demand in the market has increased year by year and sales have increased steadily. Our company maintains a high inventory to ensure that customers are able to obtain the products they need in a short time. At the same time, flexible supply chain management helps us cope with orders of different sizes, ensuring timely delivery and meeting customers' customized needs.

Dyed RPOM, as a recycled material with excellent performance, environmental properties and color customization capabilities, has become an important green material choice in several industries, providing customers with economical, sustainable and high-quality solutions.