OBP (Ocean Bound Plastic )

Ocean Bound Plastic (OBP) refers to discarded plastics that are transported to the edge of the ocean due to various natural factors before entering the ocean, and mainly originates from poorly managed areas with inefficient garbage disposal and within 50 kilometers of the coast. If these plastics are not recycled, they are very likely to enter the ocean, posing a serious threat to the marine ecosystem.

-

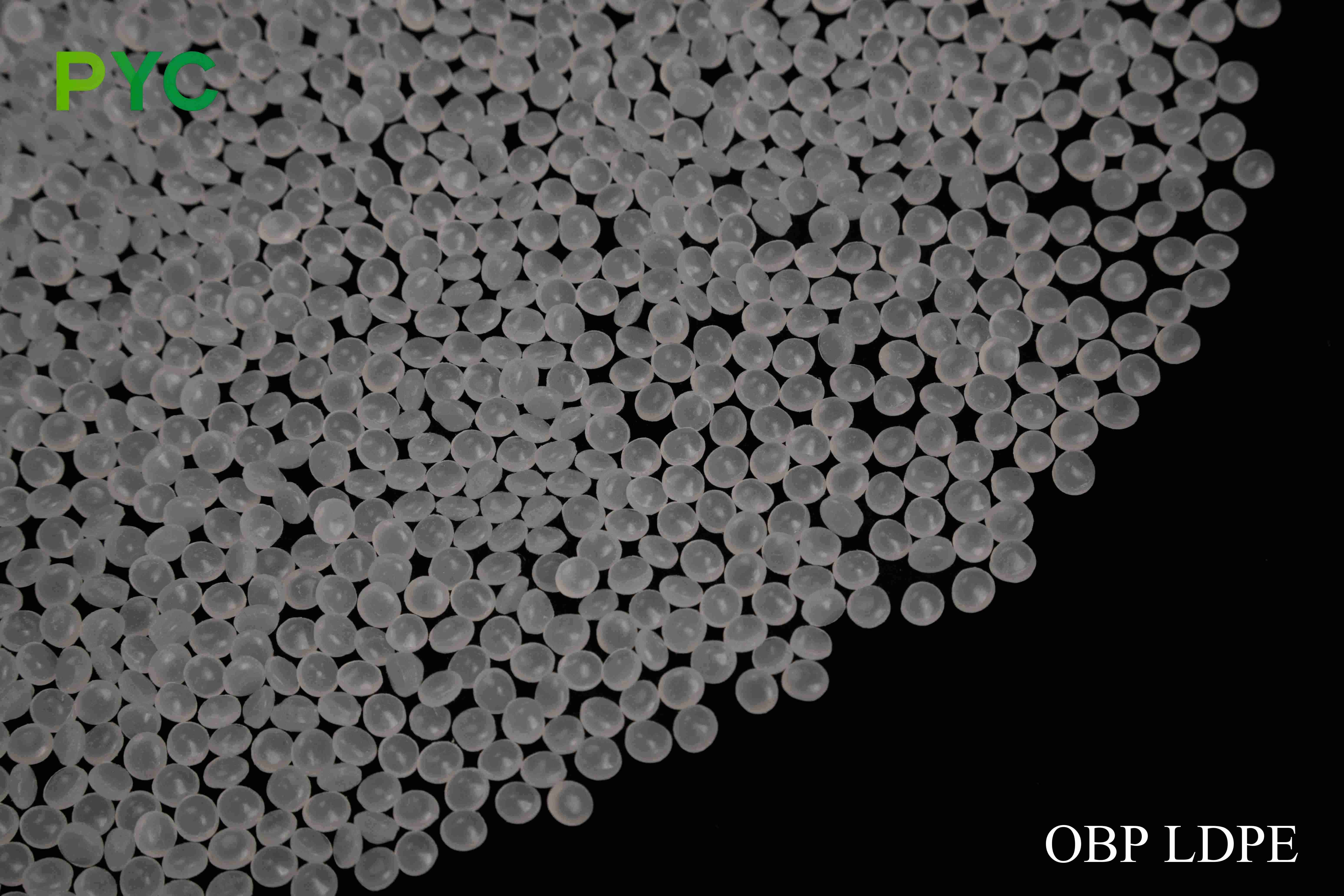

OBP LDPE

Our OBP LDPE (Ocean-Bound Plastic Low-Density Polyethylene) is an eco-friendly material sourced from plastic waste collected near coastal areas, preventing it from entering the ocean. This sustainable LDPE alternative retains the excellent flexibility, impact resistance, and processability of traditional LDPE while promoting environmental responsibility.

Email Details -

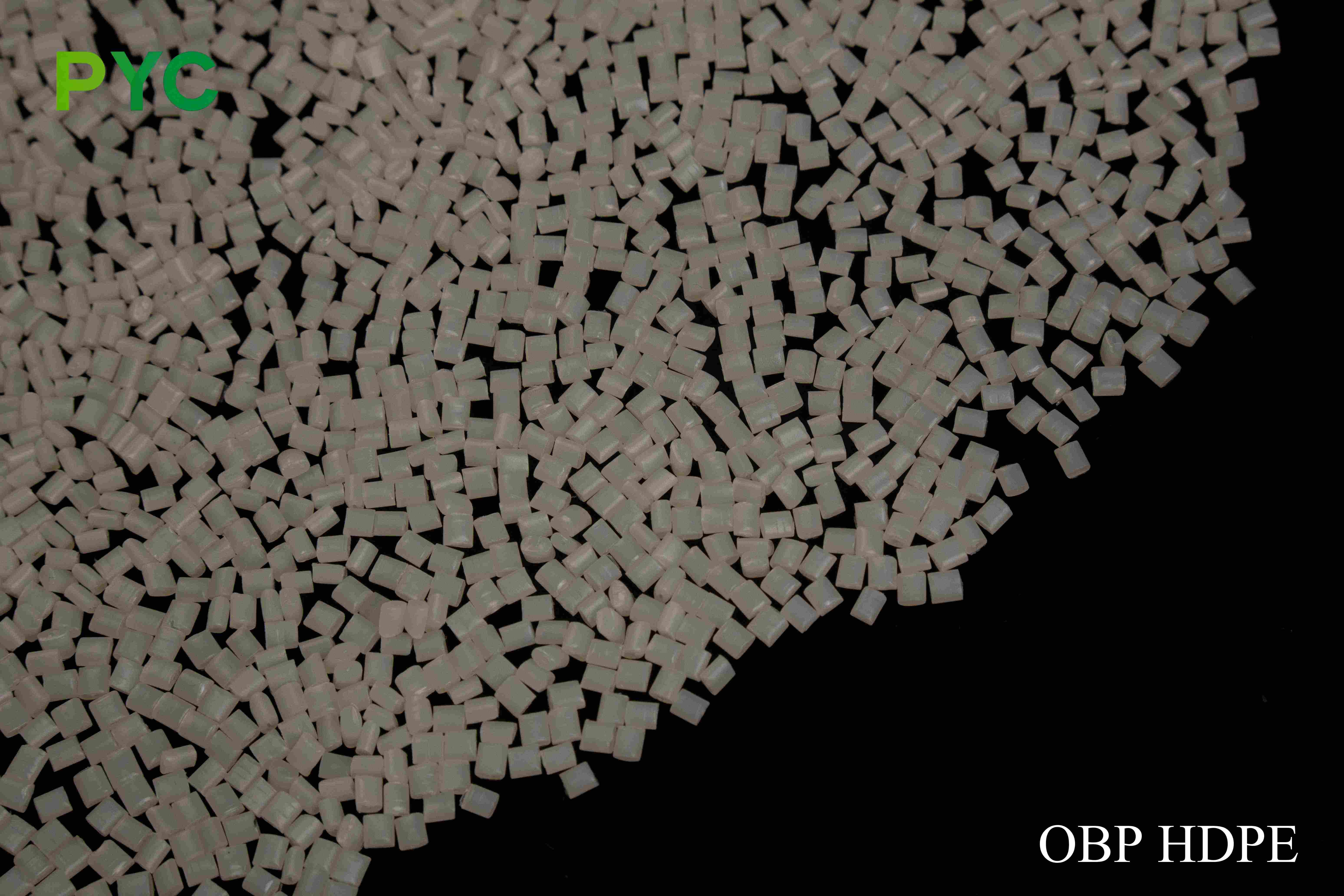

OBP HDPE

OBP HDPE is an environmentally friendly material made by recycling Ocean Bound Plastic (OBP) waste, consisting mainly of high-density polyethylene (HDPE). Ocean bound plastic refers to those plastic waste that comes within 50km of the shoreline and often ends up in the ocean, causing serious environmental pollution. By recycling this plastic waste, OBP HDPE not only helps to reduce plastic pollution, but also promotes the recycling of resources and environmentally friendly production, in line with sustainable development requirements.

Email Details -

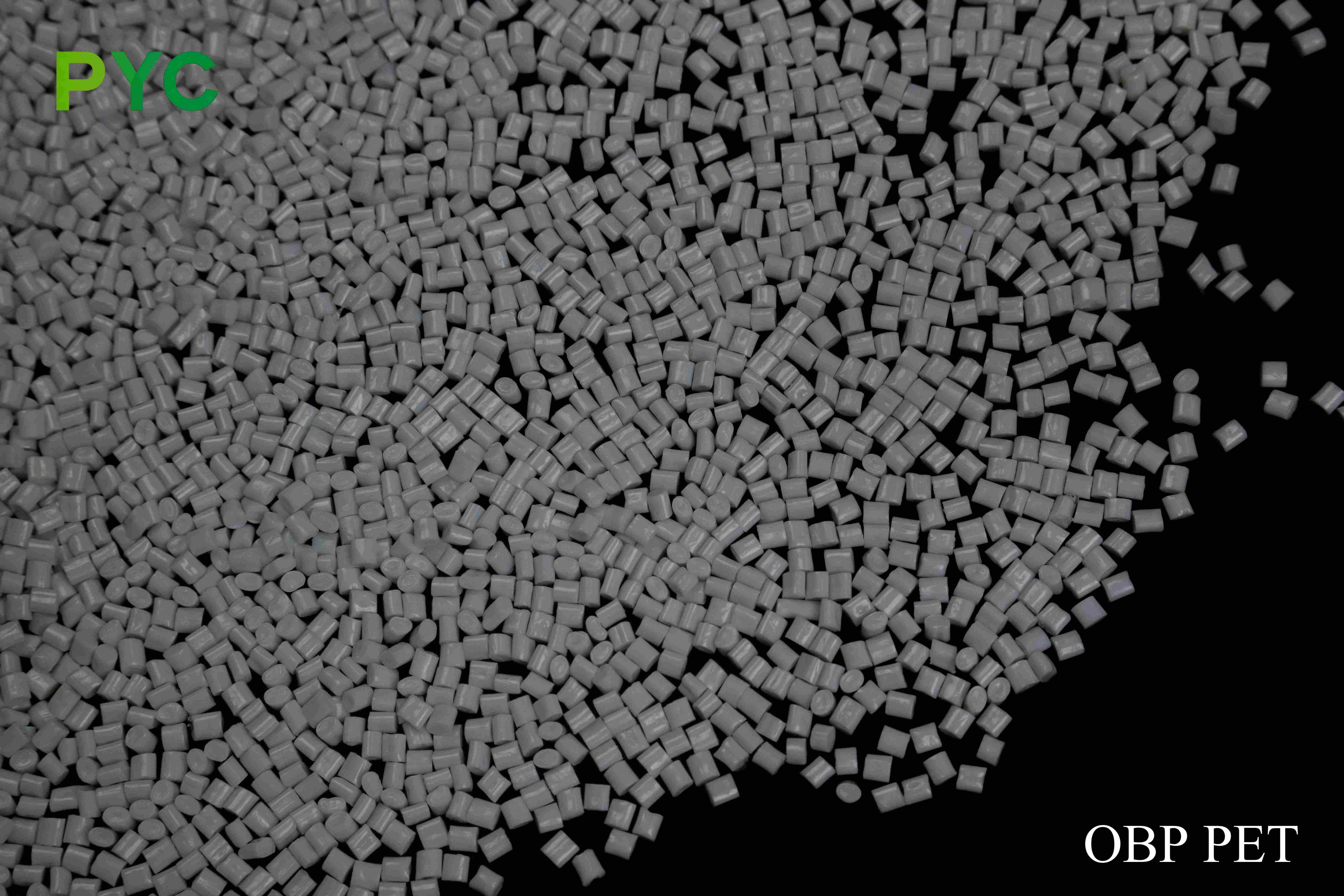

OBP PET

Our OBP PET is a high-performance material that combines the benefits of Optical Brightening Agents (OBAs) with the durability and versatility of Polyethylene Terephthalate (PET). This product is specifically engineered to enhance the brightness and optical appearance of PET-based applications, making it an ideal choice for products requiring high visual appeal and clarity. With excellent mechanical properties and environmental resistance, OBP PET serves a wide range of industries.

Email Details -

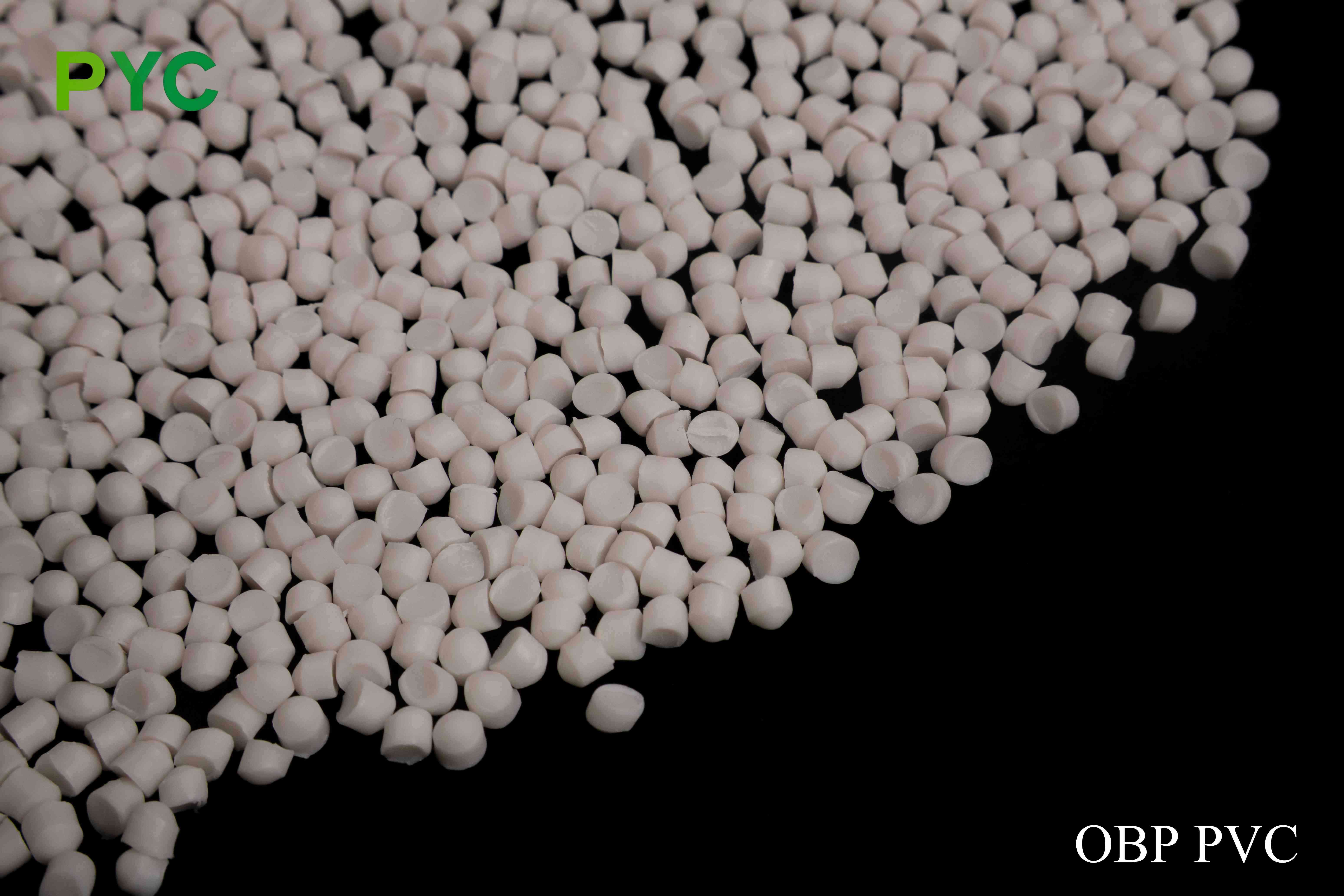

OBP PVC

Product Highlights

Email Details

High quality recycled raw material source

OBP PVC (polyvinyl chloride for Marine plastic recycling) is derived from plastic waste that is on the verge of entering the ocean, mainly including:

Discarded fishing supplies: old fishing nets, buoys, fish boxes, plastic ropes, etc.

Construction and pipe waste: discarded PVC pipes, door and window frames, guardrail and other building materials near the shoreline.

Industrial packaging materials: PVC film, tarps, cable sheathing and other industrial products.

These recycled materials undergo rigorous screening, deep cleaning and fine sorting to ensure high purity and stability of the material to meet the needs of different applications.

Strict quality control

Raw material screening: remove impurities and pollutants to ensure that recycled PVC has a high purity.

Efficient cleaning: The use of environmentally friendly solvent cleaning, remove salt, oil and attachments, improve the cleanliness of materials.

Optimization regeneration: through high temperature melting, filtration, modification and other processes, improve the weather resistance and mechanical properties of PVC.

Quality testing: Strict testing of tensile strength, impact toughness, thermal stability and other key indicators to ensure that products meet industry standards.

Excellent performance, widely used

OBP PVC has good corrosion resistance, aging resistance and excellent mechanical properties, suitable for:

Construction industry: recycled PVC pipes, profiles, guardrail, waterproof materials.

Industrial application: cable sheath, auto parts, chemical equipment protective layer.

Fishery and Marine engineering: fishing nets, buoys, Marine floats, etc.

OBP PVC provides high performance and environmental protection PVC material solutions for sustainable development through high purity selected raw materials and strict quality control.