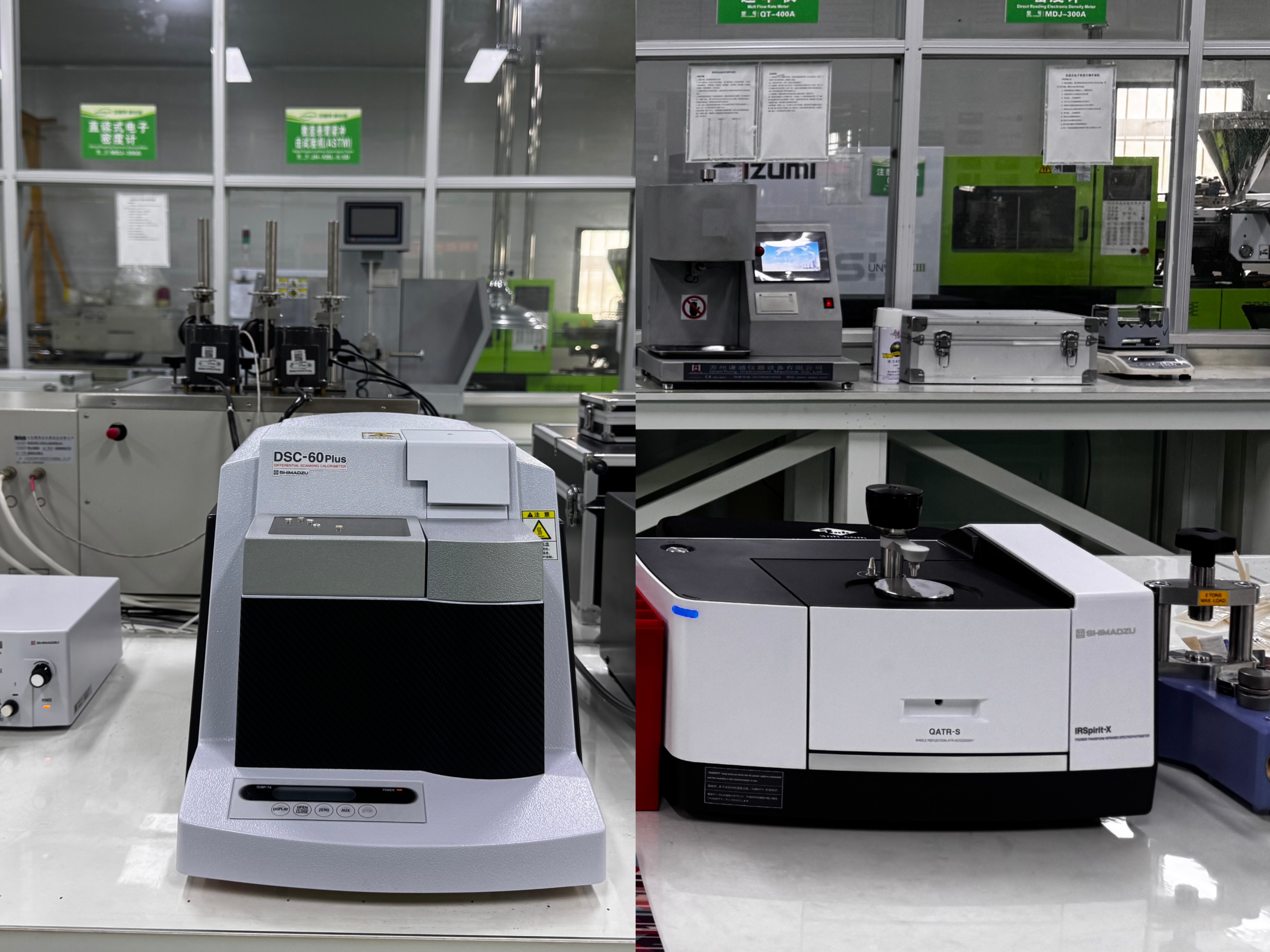

Pingyuan Company's laboratory has introduced high-end detection equipment from Shimadzu of Japan and completed technical training.

September 13, 2025 - Henan Pingyuan New Materials Technology Co., Ltd. recently officially put into use the Shimadzu Fourier Transform Infrared Spectrometer (FTIR) and the Shimadzu DSC-60 Plus Differential Scanning Calorimeter (DSC), and jointly completed specialized training with the technical team of Shimadzu Corporation. This upgrade has further strengthened the company's technical capabilities in the analysis of recycled plastic components and the characterization of thermal properties, providing precise data support for the research and development of high-value recycled plastic products.

Technology Upgrade: Precise Analysis Empowers R&D Innovation

The newly introduced FTIR and DSC equipment can quickly detect impurities and molecular structures in recycled plastics, precisely analyze key parameters such as material thermal stability and melting characteristics, and help optimize product processes and upgrade product quality. For example, by identifying the molecular features of ocean plastics (OBP) using FTIR and optimizing processing temperatures with DSC, the application performance of recycled plastics in high-end packaging, medical devices, electronic appliances, automotive and other fields can be significantly improved.

Training Empowerment: Deep Integration of Theory and Practice

The technical expert team of Shimadzu Corporation provided a two-day theoretical lecture and practical guidance, systematically explaining the equipment principles, operation norms and data analysis methods. The training covered:

• Instrument operation: FTIR light source calibration, DSC sample preparation and temperature program setting;

• Data analysis: baseline correction, thermal flow curve analysis and detection report generation;

• Fault diagnosis: common abnormal handling and safety operation norms.

Laboratory technical experts mastered the entire process skills from sample testing to data interpretation through group practical operations, laying the foundation for the efficient application of the equipment.

Green Outlook: Technological Synergy Drives Circular Economy

As a national high-tech enterprise, Pingyuan New Materials relies on research platforms such as the Institute of Process Engineering of the Chinese Academy of Sciences to build a domestic high-standard laboratory for recycled plastics industry. After this equipment upgrade, the company will further explore the combined technology of spectroscopy analysis and thermal analysis, optimize the molecular-level application process of recycled plastics, reduce energy consumption and increase product value-added.

About Henan Pingyuan New Materials Technology Co., Ltd.

The company was established in 2017 and focuses on the research and development of recycled plastic recycling technology. It has obtained multiple qualifications such as GRS global recycling standard certification and US UL OBP marine plastic certification. It processes over 30,000 tons of waste plastics annually and serves over 800 customers worldwide.